General Motors is investing heavily in all-electric future, vying to achieve the top spot in electric vehicle market share in North America. To that end, GM has just unveiled its new Ultium Drive motor technology.

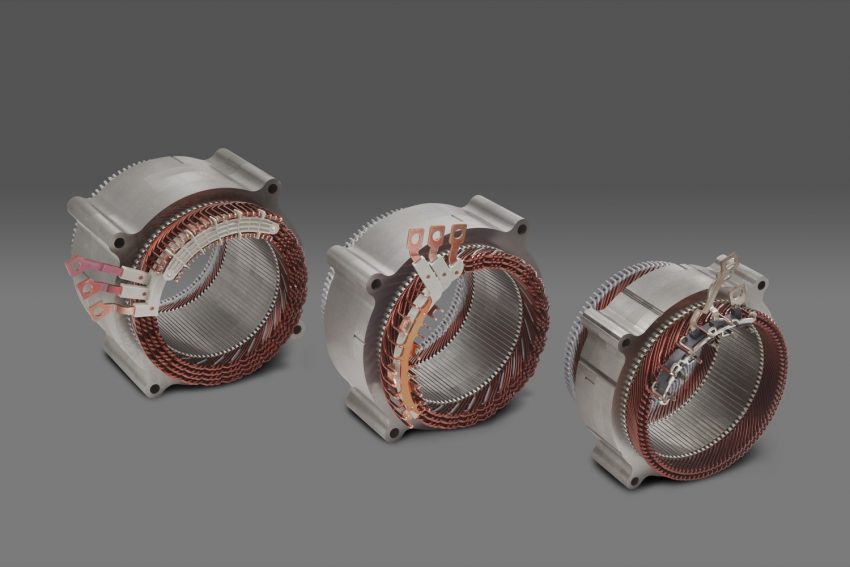

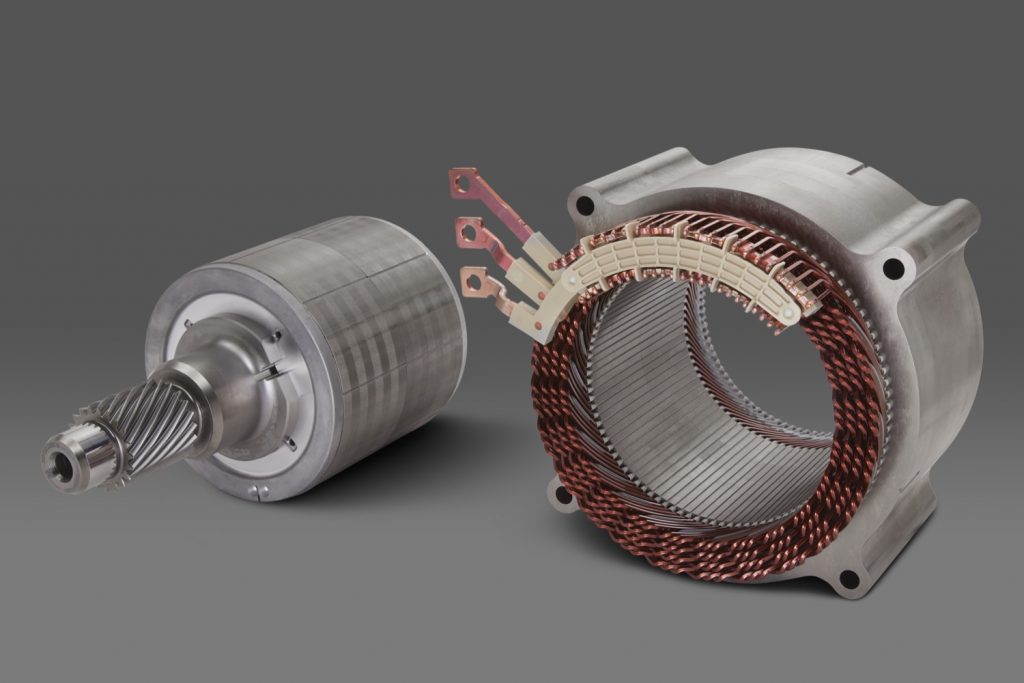

During the ongoing 2021 Mackinac Policy Conference, GM President Mark Reuss introduced three new all-electric Ultium Drive motors intended for use in General Motors’ Ultium-based models. The three motors include a 180-kW front-drive motor, a 255-kW rear- and front-drive motors, and a 62-kW all-wheel drive assist motor. The 62-kW unit is an induction motor, while the 180-kW and 255-kW units are permanent magnet motors designed to minimize reliance on heavy rare earth materials.

“Twenty years of electric drive system development and more than 100 years of high-volume vehicle engineering are helping GM pivot quickly from conventional vehicles to EVs,” Reuss said during the debut. “Our vertical integration in this space, encompassing both hardware and software, helps give us control over our own destiny and a significant competitive advantage.”

The motors were conceived as part of a scalable family, sharing similar design principles, tooling, and manufacturing strategies, thus reducing the number of parts involved in bringing the new Ultium Drive motors to market. The three motors will be used in myriad applications, from work trucks to performance vehicles.

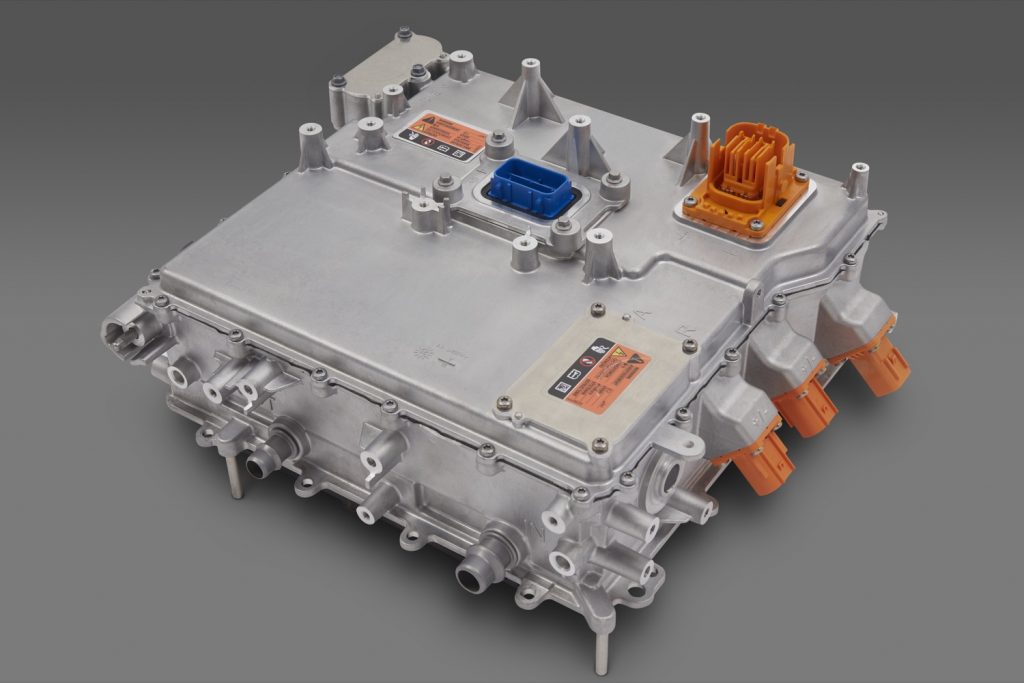

In addition to revealing the three new Ultium Drive electric motors, General Motors also discussed new software used to run the hardware. GM engineers based out of GM’s Global Technical Center in Warren, Michigan, Global Propulsion Systems in Pontiac, Michigan, and the Milford Proving Ground collaborated with nearly 11,000 GM product development team members in developing the new Ultium Drive software, using computer-assisted and virtual engineering as part of the development process.

General Motors states that the new software can be reused in numerous applications, providing quick go-to-market times and expansion of GM’s EV portfolio. GM also anticipates that some of the electronics will have half the mass and volume of current equivalents, and as much as 25 percent more capability.

The 2022 GMC Hummer EV will be the first General Motors vehicle to debut the new Ultium Drive motors and integrated power electronics, with the range-topping Edition 1 equipped with three separate 255-kW motors to produce upwards of 1,000 horsepower.

Subscribe to GM Authority for more General Motors electric vehicle news, General Motors technology news, and around-the-clock GM news coverage.

Comments

Hopefully future vehicles will have Frunks. (I know the Hummer Does)

Something the size of the Lyriq should have a huge Frunk.

Maybe the size/placement of the front motor to accommodate awd takes up enough space that makes a useful frunk unrealistic?

Seems rather silly that you keep harping on such a negligible feature. Seems like you’ve fallen under the Elon crowd and everyone has to do what Tesla does.

it’s not really about being Under the ‘Elon Crowd’… it’s about giving consumers choice. Because ultimately, if one manufacturer can pull off a feat, why can’t other automakers? and if they can, and choose not to do so, and list it as a priority, the question becomes ‘Why not’. This isn’t a race against other electric auto manufacturers, but rather a race against the very own ICE vehicles each manufacturer has sold prior.

@SonicFan

Exactly. If a startup like Tesla, Lucid, and Nio can figure out how to have Frunks, it is inexcusable for GM to have a vehicle the size of the Lyriq without one. Same goes for Mercedes EQS.

Some believe that Legacy Automakers on their Sedans/CUV’s chose not to place Frunks as they do not want people to realize just how much more superior in space a BEV is to their ICE counterparts at the dealerships. But I feel that Sandy Munro is correct and it is too many Legacy Parts that are being used.

Looking at the size of these, they aren’t any smaller than a small block. You could actually drop a “funk” on top of a 5.3 if you took off the big plastic cover and readjusted the air intake.

How can you tell the size of these motors, from the photos?

GM has long showed the ultium platform. Motors, battery, trans axles and inverters. These motors are about the size of a V6

But, there is a thing called cooling and air flow… I frunk would block that in an ICE vehicle.

EV’s also need lots of cooling in case you haven’t seen an eletric motor before, all the air passages and fan at the end, though in this case it looks like ultium motors are liquid cooled and will still use a radiator.

No where near as much as an ICE does.

Yes I do like my Tesla. Yes I harp on Frunks because once you have one, you do not want to go back to not having one. The Lyriq is a pretty big vehicle so it is inexcusable for it NOT to have a Frunk. Just like the Mercedes EQS.

Tesla is not the only Automaker that offers Frunks. Every Startup EV maker has Frunks.

It seems that ONLY Legacy Automakers are choosing to make some models without Frunks. It is due to them utilizing Parts Bin items that are not conducive to being placed in EV’s.

If you follow Sandy Munro he explains it in great detail. Legacy Automakers have too many Parts that they purchase in droves to save money. But those parts should not be in BEV’s not just for the Frunk aspect but for weight and efficiency reasons.

I have a Model Y, opened the Frunk once to throw the charging bag in there, and have never opened it since. That frunk door is so flimsy, feels like you could break it so easily…

I have a model 3. We use the frunk all the time. The door isnt flimsy at all.

Not having the frunk is a deal breaker for me on EVs. There isnt a valid excuse. Sorry. I love the lyriq and was strongly considering it at some point in the future. It is supposed to be a ground up design. They should have put this on the list of must haves when developing it.

I heard in Europe the lyriq will have a frunk but not USA so we can have at home fast chargers. Bad move if you ask me.

Mach E has a frunk and it is a legacy brand.

It was somewhat acceptable on the bolt because that was designed using old practices. Not Ultium

It depends on the body styling of the vehicle. The Tesla models 3, S and Y are are more of a traditional three box design with more space in the front of the car leaving room for a front stage compartment, (Albeit a fairly shallow compartment) Kona EV, LEAF and Bolt EV are more cab-forward bull nose with a shallower rake to the front glass. That leads to vertical stack of the front running gear without empty space for a storage compartment. And yes, the latter are adaptations of styling originally designed to contain an internal combustion engine.

People who desire front storage have choices from Tesla and other shoppers can pick one of the mini-CUV styles from the other manufacturers. The LG battery woes not withstanding, they’re all pretty decent vehicles.

Given the spaghetti that tends to be under those frunks I would prefer them not to have it, or add a small space to include things like a jack, compressors and free space in the rear. The people I know that have frunks just don’t use them.

Frunks on trucks is a different story because they provide lockable storage.

@theflew…I was thinking the exact same thing after reviewing those videos that group (whose name escapes me) does ripping apart the Mach E frunk and see what you call spaghetti stuff! I guess even the mach E was thrown together.

Spaghetti is true. There are two, possibly three, coolant loops and possibly two refrigerant loops. You’ve got traction motor, battery and cabin which all may be calling for different temperatures. It gets even more complicated in vehicles which use heat pump mode because there has to be a four-way reversing valve and associated plumbing.

I had a first generation LEAF which I bought used. Nissan hadn’t figured out to put the charger inverter under the hood yet and had it mounted way in the back of the car and had coolant lines all the way to the back as well. The LEAF had three electric coolant pumps. One pump was in a dedicated loop for cabin heat which was generated by liquid immersion PTC heaters. The other two pumps were in series in the main loop for the traction motor. One pump was underneath the 12 Volt battery on the driver side of the car and the second pump was mounted on the passenger side fender well. There were long hoses all over the place. One of the pumps on my car failed, which caused the ECU to kick the remaining pump into quite audible over-drive and a big yellow “!” To light on the instrument cluster. The OBD-II code indicated “Right water pump PWM output stuck HIGH.” I shopped around and fount a new replacement pump for $400, list ~$900. Ouch! I checked with a Nissan dealer to see what they wanted, which was $2500 for the job. The Nissan shop manual called for a ridiculous total drain, fill and burp of the coolant system. No wonder the dealer wanted so much money. What was much more practical is what I did. Clamp the hoses on both sides of the bad pump. Pour the coolant out of the bad pump into the new pump, install and unclamp. I did it myself in under an hour outside in cold rainy fall weather.

Brag,brag, brag, meanwhile Ford quietly leapfrogs ahead of gm in technology!

Would be interesting to see how these Ultium motors compare to Tesla, Lucid, and GM’s existing Bolt motors in terms of power, weight, and external volume.

The hair pin stator construction on the Bolt and Ultium motors looks well thought out and is probably cheaper to manufacture than the windings used in Tesla’s motors. Like Tesla, GM uses a stepped laminated rotor with permanent magnets. From a customer standpoint, I doubt most customers would care much about the technical aspects of the motor as long as it works and it is reliable. I have a 2017 Bolt and I give GM a lot of credit for doing a very good job with the control firmware and integration with the hydraulic friction braking system. The proportioning between regeneration and friction braking is stepless. Even at very low crawler speed there is no discernible cogging of the Bolt motor. No doubt the Ultium motors are better, given four more years to hone the design. I owned a used 1st generation Nissan LEAF for a while and it was nasty in comparison: definite motor cogging and the cross-over from regeneration to friction was glaringly obvious. I’ll give some credit to Tesla in that they have an oil filter which is accessible without taking the transaxle apart – how important that is remains to be seen.

As for GM making electric vehicles for over 100 years…. Yes, we’ll sort of, if one counts railroad locomotives and forklifts. I have a bit of skepticism of how that experience scales to a contemporary EV. GM does get some points going back to the 1960s when they prototyped the Electrovair Corvair EV and also electrified a few GM vans. And of course there’s the EV-1 née Chevy Impact. (They didn’t do too well on that first try at the name!)

Great as long as it is not decided to manufacture them in Mexico or share the technology with the Chinese partners.

I personally would love to see a matchup comparing all the EV manufacturers electric motors. Tesla makes great motors and keep updating them but when Porsche brought out their Taycan they copied the gm design format. Must be something that they tested and found out? Also everyone keeps mentioning the cooling that these motors need why isn’t this heat used to warm the vehicles interior during cold months up in the North? Any engineers with an answer out there? Using my Bolt as an example the electrical amount usage running the air conditioner isn’t bad at all but using the heater kills the battery as bad as driving 90 miles an hour.

Motor and or power electronics heat is harvested for the battery or interior in Most Modern EV’s. Tesla uses one system for all heating and cooling, can work in any number of ways through the octovalve.

Any electric motor is more efficient at lower temperatures. Heat causes an increase in resistance. EVs biggest heat problem is keeping the batteries cool at a safe temperature on discharge or charging. Heat is detrimental to the life of any battery.

It always takes more to heat a space than to cool it on our ambient temperature. If it is 90 F cooling it is 20 degrees different. Heating from 30 F to 70 F is a 40 degree difference that takes more energy.

cool

Yes I totally agree with the other comments that say these look pretty good…. Looks fairly run of the mill to me, but I think this is a good thing – and standardizing on only 3 Stators/Rotors surely will hold production costs in check….. GM is thinking ahead to be reliable and profitable from the start of the program….

As far as the cooling required by the propulsion battery, drive motor(s), 11.4 to 19.2 kw Car Charger, 14.4 volt power pack (probably 170 amperes in the Lyriq) , and Inverter modules – there is no need to get panties in a bunch here…..

All cars in this price range have air conditioning systems, so the fan cooling used during charging, as well as the refrigeration used during fast-charging, and/or operation in hot climates is necessary for the passenger cabin anyway…. Yes they have a few additional loops but seems to me they have minimized the cost – especially the cost-reduced system used in the BOLT ev and BOLT EUV… I know as far as ‘Ultium’ goes, that this is a separate – more modern system – but I’d expect the wise cost-efficiency used in the BOLT(s) to carry over to future Ultium products.