As the number of COVID-19 patients continues to grow, General Motors has repurposed its production facility in Kokomo, Indiana, to build much-needed medical ventilators. However, in order to protect the health of those workers onsite building the devices, GM has also put into place strict new protocols.

General Motors is now training employees in the “extensive screening, cleaning and other CDC-recommended procedures that will be in place when volume production of Ventec Life Systems’ critical care ventilator begins in less than two weeks,” reads a GM press release. Upwards of 1,000 workers will join the effort to produce the new medical devices, including existing General Motors employees and new local hires.

However, to protect the health of the workers, those arriving at the Kokomo facility are required to sanitize their hands and have their temperature checked with a non-contact thermometer. Those working onsite will also wear medical-grade protective masks, some of which come from General Motors’ mask production efforts in Michigan.

Workers clean their workstations between shifts, while cleaning crews are also in place to sanitize touch surfaces three times per shift. Workers are reminded by signage to practice social distancing. To that end, each workstations are staggered in six-foot increments. Workers also enter and exit through different doors to help minimize contact.

“Every ventilator we build can help save lives, and GM’s global supply base and manufacturing teams, the UAW, and Kokomo community are working with passion and unwavering commitment to get the job done,” said General Motors executive vice president of Global Manufacturing, Gerald Johnson. “People have moved mountains to help increase production of Ventec’s critical care ventilator and we are just weeks away from delivering these lifesaving devices. I have never seen anything like it in my career.”

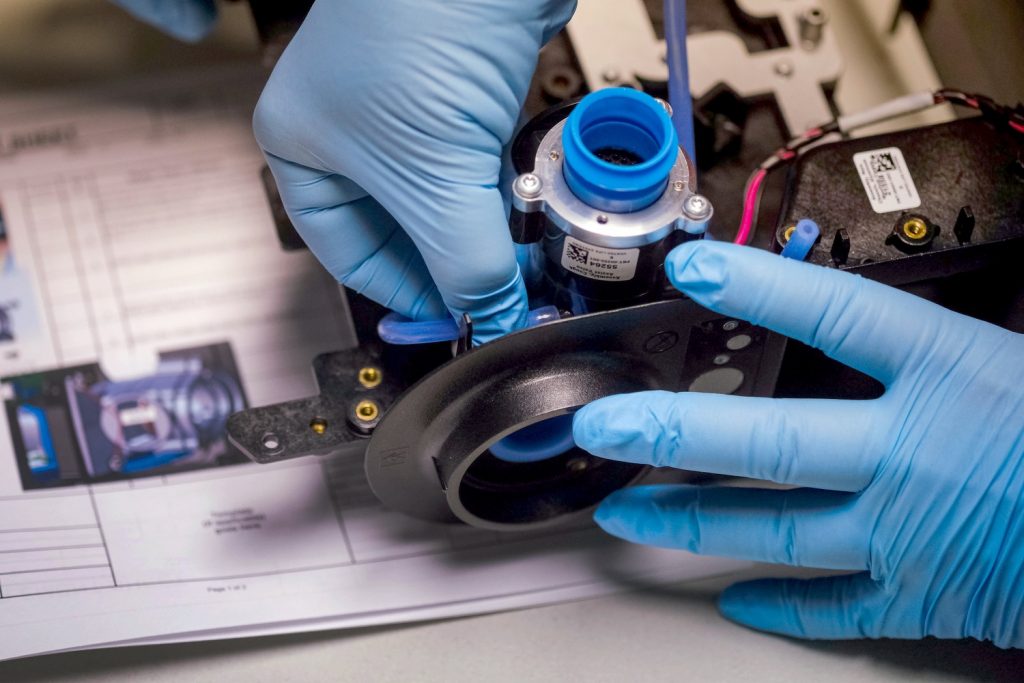

The General Motors production facility in Kokomo, Indiana, originally produced small electronic components for GM vehicles, including engine, transmission, and airbag modules, as well as sensors and circuit board assemblies. Now, GM hopes to ramp up production of the new ventilators to upwards of 10,000 units per month by mid-April.

Subscribe to GM Authority for more GM-related COVID-19 news and around-the-clock GM news coverage.

Comments

Is this really happening????????

https://www.breitbart.com/politics/2020/04/02/supply-shortage-sourced-from-china-plagues-fords-ventilator-production/

Cadriver

I stopped reading Breitbart. During their “Adolf Hitler misunderstood genius” series of articles.

So its not true?

Cadriver

Who knows? Breitbart has a history of inaccurate reporting.

What is true is Ford said they will build 50,000 ventilators in the next 100 days. I read that to mean most of those ventilators will be arriving in June and early July.

Way to go GM!!! 👏👏Just in time for the NEXT pandemic. 😷🙄 Hopefully, Gov Cuomo will purchase a few thousand for NYC THIS time around and not stash them in a Jersey warehouse again & blame the FEDs.

Michael Moss

GM’s ventilators are too late for New York, but Just in time for Texas. Gotta protect those pickup truck buyers.