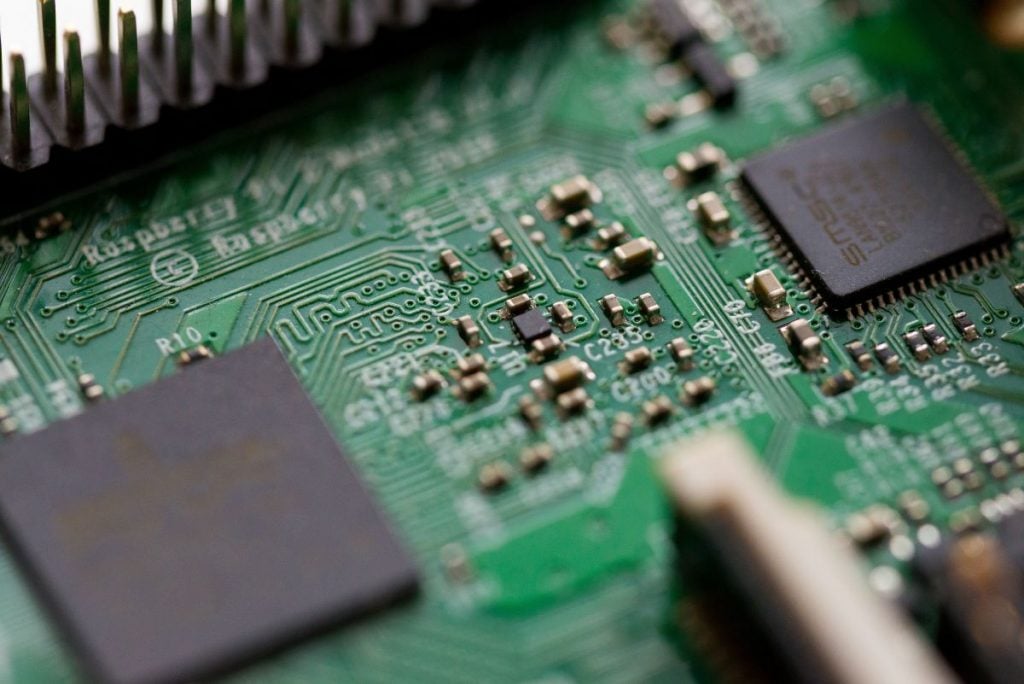

Just like the broader automotive industry, the ongoing global microchip shortage has had a profound impact on General Motors, forcing the automaker to cut production and reduce features across its lineup. Now, The General is seeking to curb the effects of the chip shortage with its own family of mircocontrollers.

During an investor conference earlier today, General Motors President Mark Reuss stated that GM was working with seven major microchip suppliers to develop three new microcontroller families in order to reduce the complexity and cost involved in implementing automobile features, as well as create a more stable source of these vital components. Reuss listed the supplier partners as including Qualcomm, STM, TSMC, Renesas, ON Semi, NXP, and Infineon. Reuss also said that the investment into the new microcontroller families would primarily “flow to the U.S. and Canada.”

Reuss stated that automotive semiconductor requirements are expected to more than double in the next few years as electric vehicles and next-generation vehicle technologies (including autonomous features like the GM Super Cruise) begin to hit the market. As such, securing a stable source of volume components for these vehicles and features is critical.

However, while many General Motors vehicles currently use a wealth of different chips for these features, the proposed families of microcontrollers will help to consolidate the various functions. Reuss stated that the new microcontrollers will be built in high volume, with as much as 10 million units annually for just one of the three microcontroller families as General Motors works to “develop an ecosystem that is much more resilient, more scalable and always there to meet our needs.” It is estimated that the three new microcontroller families will reduce the number of unique chips by as much as 95 percent.

Throughout the 2021 calendar year, General Motors has worked to combat the effects of the global microchip shortage, cutting production and features across its lineup, with the latest feature reduction affecting heated seats, ventilated seats, and heated steering wheels for a variety of GM crossovers, SUVs, and pickups.

Subscribe to GM Authority for more General Motors production news, General Motors business news, General Motors technology news, and around-the-clock GM news coverage.

Comments

I was curious what the difference is between microchips, microprocessors and microcontrollers, here’s what I found…

Both microcontrollers and microprocessors can be called microchips. What differentiates the former two is microprocessors are CPUs (Central Processing Units), they can process data and that’s it. Whereas microcontrollers are a combination of a CPU with memory (RAM, ROM, EPROM, or EEPROM), and are programmable input/output peripherals in one single package, basically an entire computer on a chip.

http://www.samuelaclarke.com/2011/08/robotics-microcontroller-microprocessor-or-microchip/

I heard Mark talk about this on the Barclays call, sounds like an entirely new system architecture is in the works, This is good news, as VIP was designed in a different time period, and does not have all the capabilities that GM needs moving forward.

Sure you did big shot. 🙄

Don’t need to be a big shot the call was open to all investors…

Nobody called me.

Don’t question him bro. That guy has a nickname around here, people here call him the prophet.

The new architecture recently developed by GM is clearly inefficient. One thing to respect about Stellantis Carlos Taveres is that not a penny is wasted, simplicity is key, which explains the companies EU margins. The cars aren’t exciting but, then again, neither arealibu, Spark, Trailblazer, Encore, Nox or Traverse.

Another solution would be for GM to buy a chip maker and make this yet another wannabe technology division.

… ok… next we are buying GM Laptops. lets see …………………………………………………… irony off

About time, I don’t need a supercomputer just to control my power seat.

I was curious what the difference is between microchips, microprocessors and microcontrollers, here’s what I found…

Both microcontrollers and microprocessors can be called microchips. What differentiates the former two is microprocessors are CPUs (Central Processing Units), they can process data and that’s it. Whereas microcontrollers are a combination of a CPU with memory (RAM, ROM, EPROM, or EEPROM), and are programmable input/output peripherals in one single package, basically an entire computer on a chip.

PS: this is a repost because the first version included a link and any comments on GMI with a link end up abandoned in moderation land awaiting attention. Sometimes GMI reminds me of those companies that always leave the “OPEN” sign on after they’ve left for the night.

if you want links put them in *code* */code* replace * with closed brackets < on either side.

Much obliged I’ll give it a shot next time.

I’ve read previously that chip makers roll their eyes at the supposed “chip shortage” that automakers experience, explaining that most other industries that rely on microchips have moved on to newer versions, but many auto manufacturers rely on older design microchips that the chip makers have moved away from and don’t make in great quantities. I’m hoping this is GM’s effort to modernize their electronics architecture and put themselves in a better position to avoid these shortages in the future.

There are multiple types of chips, the ones in the most demand right now are power control chips, and everybody uses the same ones, even Tesla is delivering cars without wireless phone chargers , and USB plugs now.

They rely on older fabrication processes (bigger transistors). The reason is that the chips in your car are often safety critical and must work perfectly for 20+ years under 185 Fahrenheit+ operation. If your ECU, power steering, ABS or airbag computer crashes while driving, you may very well get into a fatal accident. This is unlike a smartphone which gets smashed in 3 years anyway.

Automotive chips require expensive qualification and testing, and once that’s done, nobody wants to spend the time and money do it again. Often, by the time they make sure there’s no problems, the chipmaker’s bleeding-edge process has moved on anyway. Aerospace and military applications have the exact same issues.

Here’s the Fortune article I saw this discussed in: fortune.com/2021/09/17/chip-makers-carmakers-time-get-out-semiconductor-stone-age/

Ej, The chip shortage is extremely real. I’ll give you a couple examples for microcontrollers. This list could easily be hundreds of lines long covering multiple type of chips also including FPGA, analog, power, and logic, but I have things to do. You can’t even get a lot of individual transistors right now. I’ve used these microcontrollers as examples here because they’re present generation chips, not old designs. The STM32H743 is what I design high end consumer electronics around and the others are automotive qualified ARM microcontrollers from Freescale (previously Motorola):

Arrow Electronics: STM32H743IIT6- Stock: 0 – Manufacturer lead time: 98 WEEKS

Arrow Electronics: SPC5746CBK1AMKU6 – Stock: 0 – Manufacturer lead time: 53 WEEKS

Mouser Electronics: SPC5746CBK1AMKU6 – Stock: 0 – Manufacturer lead time: 52 WEEKS (same part as line above, different source)

Digikey Electronics: SPC5746CBK1AMKU6 – Stock: 0 – Manufacturer lead time: 52 WEEKS (same part as line above, different source)

Mouser Electronics: SPC5775BDK3MME2 – Stock: 0 – Manufacturer lead time: 52 WEEKS

You can check stocking distributor levels yourself before repurposing reality into a conspiracy theory. The people you’ve been letting think for you on this matter have led you astray and lied to you. Please check for yourself because all stocking electronics vendors make their stocking levels publicly available.

Don’t argue with me – argue with Pat Gelsinger, CEO of Intel.

“I’ll make them as many Intel 16 [nanometer] chips as they want,” Intel chief executive Pat Gelsinger told Fortune last week during his visit to an auto industry trade show in Germany.

“It just makes no economic or strategic sense,” said Gelsinger, who came to the auto show to convince carmakers they need to let go of the distant past. “Rather than spending billions on new ‘old’ fabs, let’s spend millions to help migrate designs to modern ones.”

Will the 2023 Colorado have the motor shut off at stops?

I have an idea…. Produce them in the US. Create good jobs and protect your life line in the process. To much manufacturing is going overseas. Make American cars again!

Another gm innovation that doesn’t exist, but it’s coming folks, honest!

Surprised that Motorola was not on the General’s vendor list for microcontrollers. Cummins went to Motorola for their fuel delivery control system. Looks like Cummins is putting their eggs into the Hydrogen fuel cell basket. Toyota is leaning in this direction.

Motorola spun off their chip division in 2004 into Freescale Semiconductor which was absorbed by the previously spun-off chip division of Philips in 2015 which is called NXP Semiconductors. They all operate under the NXP hat today but Freescale products like microcontrollers still carry the Freescale logo. MIMXRT1062 is one part as an example.

In addition to what Peter said, Motorola’s analog, non-computer chips was spun off as ON Semiconductor in 1999, which you can see on the list. (Freescale/NXP took the digital computer products)

Also, there’s no “Motorola” anymore. Motorola split phones and cable boxes off to Motorola Mobility, which was purchased by Google, and then sold to Lenovo. What was left was Motorola Solutions, which is basically police and fire radio systems.