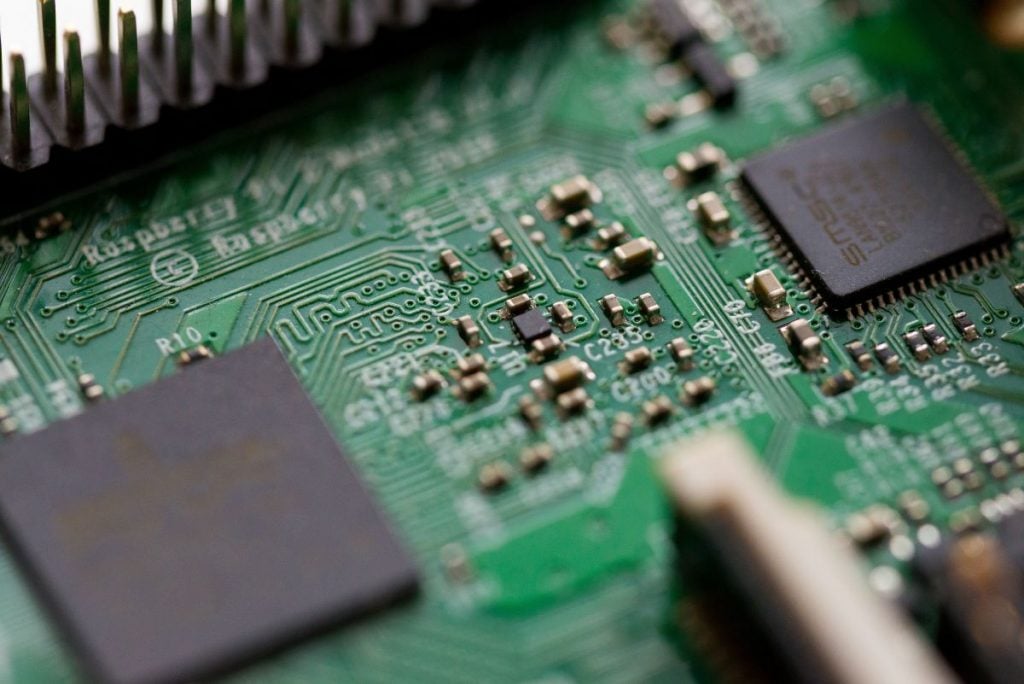

In case you’ve been under a rock for the last year or so, auto industry news has been dominated by the ongoing global microchip shortage, which has affected production and product availability for every major automaker, including GM. Now, however, GM says it will have its own family of microchips locked in by 2025, a move that is expected to offset future chip-related production delays.

In a recent interview with Associated Press, GM CEO Mary Barra said that GM is moving toward three families of microchips that the automaker will buy and control directly. This is in contrast to the older model in which GM allows parts supply companies to acquire chips without GM’s prior knowledge.

GM’s new standardization model will streamline the critical components, eliminating the need for dozens of different chips per vehicle and allowing GM to buy in bulk to ensure that supplies are not interrupted.

“We’re also working with a select group of strategic companies to source these for the volumes,” Barra told AP. “We’ll have much better control and a stable supply.”

For now, however, Barra indicated that she expects chip shortages will likely continue into next year, possibly exacerbated by further COVID-19 outbreaks.

GM aims to be the market leader in electric vehicles by mid-decade, passing the current global EV sales leader, Tesla, in just two and a half years. GM has a long way to go yet, selling only 25,000 EVs in the U.S. last year, a fraction of the 352,000 EVs sold by Tesla.

According to one recent report, EVs have reached 5 percent of new vehicle sales in the U.S., a figure that’s considered the tipping point prior to widespread adoption. To help get there, GM will offer a range of more-affordable EV models, such as the upcoming Chevy Equinox EV and Chevy Blazer EV, as well as an all-electric iteration of the popular Chevy Silverado pickup. GM plans to launch 30 new EV models globally by 2025.

Subscribe to GM Authority for more GM business news, GM technology news, GM electric vehicle news, and around-the-clock GM news coverage.

Comments

Interesting. I wonder if this switch will somewhat coincide with the transition to EVs? Maybe EVs will allow them to simplify the different types that are necessary.

Good job Mary. It’s about dang time too.

GM used to make their own semiconductors at Delco Electronics in Kokomo, Indiana. Of course they spun that business off years ago. Too much outsourcing over the years.

Based on where things are now, I’m quite sure that was a move they wish they never made.

Ok Eddie you have just become a certified xpert on global outsourcing in 1 sentence.!

Will the real GC please stand up! (-;

It says “Michigan” in picture. Is that where chips will be made?

Yes. Michigan is a town located in a northwestern province of China.

/sarc tag for the humor impaired.

That’s where Mary Barra was made.

Yes they will, gm has set a proposal late last year with a few different companies here in the US in their efforts to make their own chips, depending on Russia or China to continously supply the US with the chips or even imported materials in order to make them at this point, is a risky strategy with now signs of improvement anytime soon, f*** the Global Operatorations Strategy on this measure, we truly need to be doing for ourselves within this country right now.

Totaly agree Ray

I recall a source that claimed EVs use ~6x the number of chips that an ICE vehicle does. If Mary’s decision can result in fewer chips used per vehicle, then it’s a necessary move. I’m curious to know what architecture these chips will rely on, including potentially ARM or RISC-V.

Their software engineers can’t write an intelligent piece of code for the commodotized chips they’re currently using. How is this going to make things better?

I’ll be curious how this works. I thought for some stuff like seats, windows etc, ie commodity across companies, the tier 1/2 built it out and supplied the unit to gm. How would this work now? Or does gm currently do the assembly of things like seats? And I am pretty sure gm is still not manufacturing the chips, they are doing the design. Similar to what apple/nvidea/… do. I’d be pretty surprised if gm got into the chip biz. That would be dumb. Literally tens of billions to just get started and the equipment is impossible to get anyway. It is all sold out for a couple of years.

If I am not mistaken the GM Plant in Kokomo, Indiana produced Semiconductors until 2017 when they shut it down in a cost saving move and sent the business to Asia.

That’s the free market at work!

Unfortunately, poor, short-sighted corporate decisions are indeed part of the free market. And now consumers get to respond accordingly.

That’s corporate and consumer greed at work. The free market isn’t free when your supply chain is behind enemy lines. Globalism is a failed experiment

You are mistaken. The GM semiconductor plant became obsolete for making computer chips by the early 90’s. Part of it was Motorola and other makers stopped providing the masks and technologies to make chips. This was an industry-wide shift.

They switched to power semiconductors which aren’t behind the current shortage, and then quit.

The only two companies in the world that make your computer chips today from Taiwan and South Korea. Period. If IBM and AMD failed and quit chipmaking, a company like GM stands no chance.

So I guess I will get the chips for my second-row heated seats and auto backup assist feature (for those that failed a driving test) sometime in 2025???

Gotta love the Mary picture above with “Made in Michigan” in the background……while a good percentage of their cars are made in China and Mexico.

Absolutely tone deaf and unforgivable.

That’s the free market at work!

Shouldn’t America’s free market benefit from American government bailouts?

The sign indicates where Mary Barra was made.

40-50% China content on most US made vehicles

Yep gm sells out to the Chinese for chips and now that’s a mess so uncle Joe and congress are going to gift them 55 billion for chip manufacturing here. It really is government motors.

Your grasp of the situation is….

That is for the whole US, mostly for defense industry, Pretty bad idea to have China building chips for your fighter jets, missiles and ships. Add in some economy of scale for the whole process who knows GM may supply defense industry with a new chip architecture

Not sure why a few of the major automakers don’t team up and enter the semiconductor business. Costs would be small with multiple investors and a standardized lineup of chips. They could even sell to other sectors

Closing the GM Kokomo chip fab plant was a very bad idea. Buy using self made chips and selling to Ford and other domestic builders/assemblers, the huge increase in volume would have utilized the efficiency of volume to offset expense equipment and labor. They also already head the in-house expertise and well trained work force.

Agreed!

China doesn’t build anything for our fighter jets. Major parts of military aircraft are not allowed to be outsourced to adversary nations. Law requires domestic sources, unless the US government specifically allows it as part of a deal to sell an ALLY one of our planes (called offsets). I work for a company in Cleveland that makes frame parts for the F35. Foreign nationals are not allowed in the plant without a rigorous approval process. Until Russia invaded the Crimea in 2014, we had to compete with a Russian company for commercial aircraft forgings, but that’s a thing of the past. Airbus is hurting because they bought a great deal from the Ruskies. There are only so many big forging presses.

Ms. Barra is already in Bed with the current administration.

In the meantime, it’s a good thing they spent millions on that wimpy lower case gm logo…

GM is a loser company. All hat and no cattle. The public is so dumbed down they can not even back into a parking space. Ev does not work. Ev pollutes twice as much as ice. All lies. Biteme Biden never won the election. Car lots are empty of new vehicles because the new world order wants you to walk. F— Y–.

You are the minority, the shareholders would have sacked her in a minute if she was incompetent. I believe she has exceeded the last ten old guys that have been at the helm. Maybe Bob Lutz would have given her a run for the money.

They’re afraid to get rid of her. The radical left will label gms board as racists and try to cancel them. It’s a wonderful time we’re living in. You disagree with a liberal and you’re a racist. A lot of sick people out there

On the edge of my seat waiting to see if this comment magically disappears – deleted by the PC Gestapo. Everywhere you go, the noose is tightening…

They’re standardizing on architecture and suppliers so they are the primary/sole customer for those products This does not mean they will build fabs and manufacture their own chips as that would not be economically viable. They will lock up sourcing from a third party such as Infineon, ST Micro, etc. Yeah, GM had their own fabs back in the 80s but that’s when fabs were much less complex and far cheaper to build and operate.

GM should buy/build at least three chip factories in this country. That would do away with any kind of shortages in other countries, and competition with other buyers from chip suppliers overseas ( I’ve read that many of these factories switched production of car chips to PC and game chips, when COVID hit and everyone’s kids were home and no one was buying cars). This would also help with shipping problems. Since a chip factory takes, on average, almost 4 years to build, why didn’t any American car companies get going on chip factories here? They could have been producing right now. The Big Three could even go into this as a joint venture, making only chips for cars and trucks.

GM has how many parts plants? Why not include chip plants in the parts division?

Silly. Chip fabs (manufacturing plants) cost about $20 Billion each. The reason chip fabs went to the east is that their governments bankrolled huge investments that might not have paid off. TMSCI had a gifted leader (who grew up professionally in the US) that drove them down the hard road of innovation, and relentlessly invested in the huge capital requirements of modern chip manufacture. The problem is WALL STREET…that group of lawyers and accountants that expect huge profits every quarter, and will not invest in the industries that make us a modern nation. Accountants are killing the country, because they refuse to admit you have to spend to stay competitive. They pushed us to cut payroll and send manufacturing overseas…now look what it got us… we have trouble competing in industries we created… all so those asshats can get a bigger bonus.

Hilarious to see all these old dudes on this platform debating about whether or not we should make chips in the US….barking at each other about how they used to work at McDonnell Douglas or Boeing back in the good old days. If you guys knew how incestuous and global these manufacturing relationships are now, you would understand why companies like GM, Ford, or Apple have to use factories operating three shifts all around the world…just to keep up with global demand. Sorry but there’s not even enough workers, skilled or unskilled in the US to get it all done! You guys are all thinking analog, this problem is digital (speaking metaphorically).