GM has announced a definitive supply agreement with MP Materials, a rare-earth materials company based out of Las Vegas, Nevada, that will supply the automaker with rare-earth materials, alloy, and magnets to support GM’s all-electric vehicle programs. The new supply agreement is set to kick off late in the 2023 calendar year.

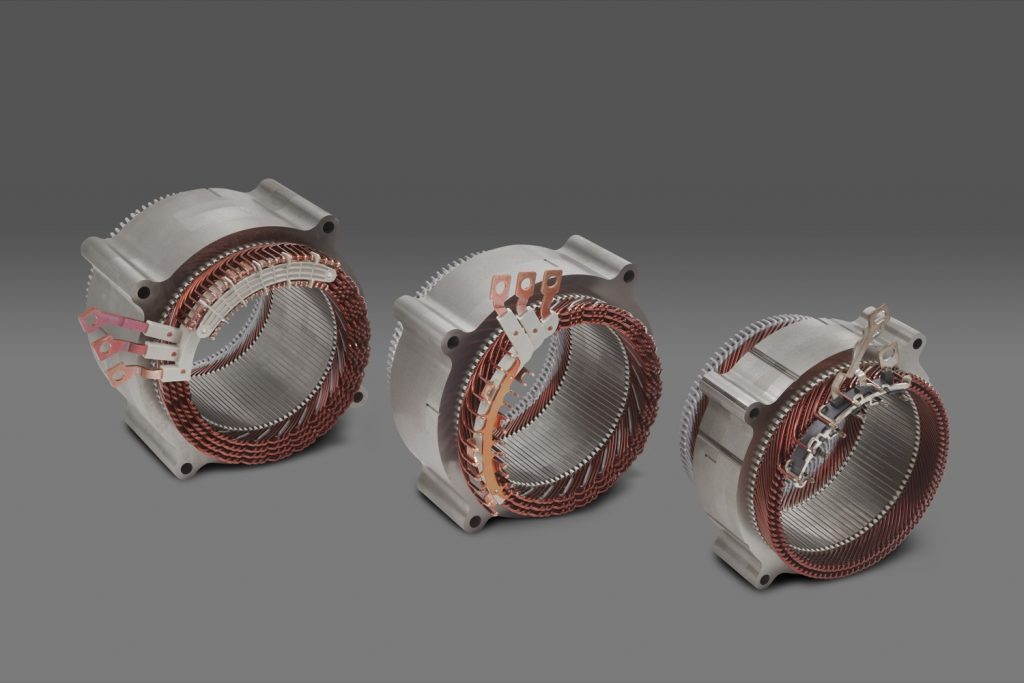

The new definitive supply agreement follows a binding agreement between GM and MP Materials announced last December. The materials, alloys, and magnets will be used in electric motors for more than a dozen GM vehicles incorporating the automaker’s Ultium technology.

In parallel to the announcement of the definitive supply agreement with GM, MP Materials has also announced the start of construction for its new rare earth magnet factory in Fort Worth, Texas, set to create an estimated 150 skilled jobs, as well as roughly 1,300 indirect jobs. The facility will source materials from Mountain Pass, California, and will have the production capacity to turn out roughly 50,000 EV motors annually, with potential to scale. That includes roughly 1,000 metric tons of neodymium-iron-boron (NdFeB) magnets per year.

The new facility is part of MP Materials’ recent $700 million investment to restore the U.S. rare earth magnetics supply chain over the course of the next two years. The facility will also integrate recycling and environmental capabilities for longterm sustainability. In addition, the company’s Mountain Pass production plant is a “closed loop, zero-discharge facility” that recycles over 1.7 billion liters of water annually, according to MP Materials.

“Bringing magnetics capabilities home is transformational for MP Materials and America’s supply chains,” said Founder, Chairman, and Chief Executive Officer, MP Materials, James Litinsky. “I am very proud that after a series of executive orders spanning multiple presidential administrations MP Materials is leading the restoration of the full supply chain and the revitalization of the American manufacturing spirit in our sector.”

As a reminder, General Motors has announced plans to launch 30 new electric vehicles globally by 2025.

Subscribe to GM Authority for more GM business news, GM electric vehicle news, GM technology news, and around-the-clock GM news coverage.

Comments

Was initially happy to see MP is a US-based company…then disappointed to see the company has (minority, but still significant) Chinese investment. I was then further disappointed to learn that the US-Gov’t has been throwing money at the MP mine (the only rare earth mine in the US) recently. Then, very disappointed to learn that the mine has a projected life of only about 20-25 years (that’s fairly soon and we only have 1, so what then?).

While trying my very best to keep my own political bias out of my analysis, all things considered, I just don’t see (for the US) the sustainable, better, etc. alternative path here (i.e. EVs broadly replacing ICE cars by the various targets being discussed)…as it has continually been jammed down our throats.

Certain groups will gain vast wealth from whichever technological path we choose…so how are we better of showing preference to Chinese and various private equity investors over the “bad” oil companies…this just stinks of corruption to me. Private equity is a very mixed bag…some do good, but some do much more harm than good (to the US and/or the overall economy), but all have far less oversight than public cos. get…

Also, while everyone in a capitalist society needs to turn a profit, in PE there is a SINGULAR focus of turning that investment into more money…public cos. have to balance more, play by more rules, and think-longer-term, and that can be a good thing when we’re talking about this magnitude of societal transformation.

Lastly, this is all about the earth & environment, right? Mining ops inherently pose very high-environmental-risks…so this is really just choosing a different way to contribute to environmental damage.

If past is prolog, in a capitalist system, what I predict will happen is, given time, re-engineered motors/other products will require less rare earths, and, looking down the tube from the other end, we’ll find new sources of rare earths. I read there is a project to “mine” coal ash (and there’s plenty of that!), and even sea water. And there’s always new mines, who knows where – Africa, Afghanistan (yes), South America, who knows.

I suspect the product re-engineering will be the biggest element in solving this issue.

The electric motor was invented 188 years ago. I would hazard a guess that it is the use of the rare earths that give the current EV motors the capacity to move vehicles using a reasonable amount of battery power.

Interesting. I’m all for bring jobs to America, but the hypocrisy concerning the Environmentalists over the last 50 years is stunning, especially in regard to California where no new industry involving mining or oil drilling, on shore or off-shore has been approached without total outrage by the leftist environmentalists. Now, consider California’s water rashioning due to statewide shortages. I know the article states it will be “closed loop, zero discharge” water use. Where will the water come from, where will it return to after “cleaning” the toxic acids from the rare earth magnetic materials. Think about it, 1.7 billion liters of water, annually, for mining of toxic material from a state that won’t even let you water your lawn in the summer. Again, I’m all for “Made in America”, but the push for every level of production of these EV’s and their hazardous material batteries is too hypocritical for me, comparing it’s entirety to the ICE’s and the complete carbon footprint of the two.

We need jobs! No, not those jobs….

Glad to hear that GM keeps locking up long term contracts as Tesla has been doing for a Decade.

GM will overtake VW Group and Toyota with the switch to BEV’s. Great job GM keep the pedal to the metal.

I am seeing quite a few items like this in financial newsletters. This site does not publish comments with links, so Google the following:

“Rivian CEO: You thought the chip shortage was bad?

The auto industry is already dealing with a semiconductor supply crunch. The EV battery supply shortage might be even worse.”

Here are excerpts from the article:

“The chip crunch, Scaringe said, would look like a “small appetizer to what we are about to feel on battery cells over the next two decades,” according to the Wall Street Journal.”

“Put very simply, all the world’s cell production combined represents well under 10% of what we will need in 10 years,” Scaringe told reporters, according to the WSJ. “Meaning, 90% to 95% of the supply chain does not exist.”

Imagine manufacturer lots sitting full of EVs that won’t be shipped until the batteries are delivered.