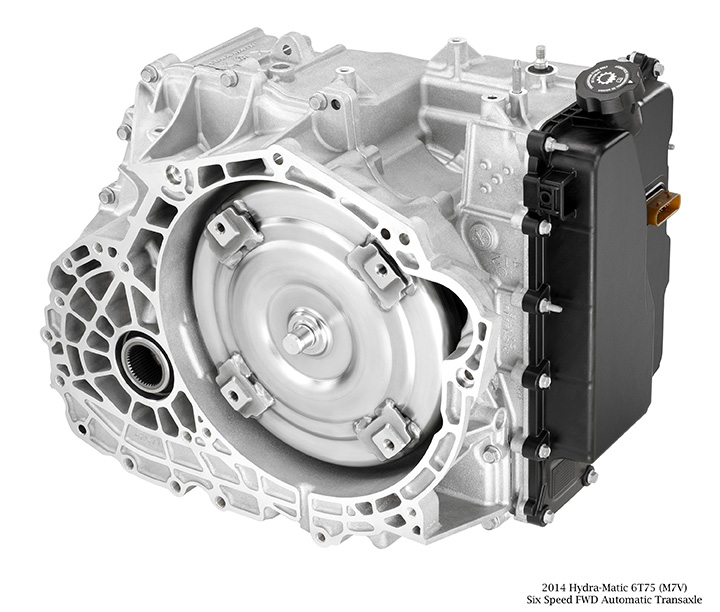

The Hydra-Matic 6T75 (production code M7V) is a six-speed automatic transmission produced by General Motors for use in front-wheel-drive vehicles with a transverse powertrain orientation. Developed in-house by General Motors, the Hydra-Matic 6T75 is part of the 6TXX family of transmissions that succeeded the 5TXX family. The 6T75 is more capable and robust than GM’s 6T50, 6T45, 6T40, and 6T30 gearboxes. The 6T75 M7X is the all-wheel-drive variant of this front-wheel-drive 6T75 M7V.

The Hydra-Matic 6T70 (MH2, MH4, M7W and M7U) and 6T75 (M7X and M7V) transmissions are part of GM’s family of technically advanced, fuel-saving six-speed automatics designed to optimize efficiency while delivering exceptional smoothness and an excellent feeling of performance. Because of the wide ratio spread, first gear is a very high ratio, which provides brisk acceleration from a stop. Sixth, however, is an overdrive ratio, which keeps the engine revolutions as low as possible for highway cruising, reducing engine friction losses and improving fuel economy.

On-Axis Design

Instead of “folding” the transmission around the end of a transversely mounted engine, which has been one of the dominant GM transaxle design conventions, the 6T70/6T75 contains all of the gearing in line with the crankshaft centerline of the engine. The advantages of this layout can translate to a shorter overall vehicle length, more interior room and lower powertrain height.

Advanced Clutch-To-Clutch Shift Operation

Three planetary gearsets are used with three stationary clutches and two rotating clutches, which save space compared to freewheeling designs. Freewheeling mechanisms allow perfect timing between shifts, but also take up more space and add more components to the transmission. However, due to the electronic controls, the clutch-to-clutch concept of the 6T70/6T75 delivers the same accurate shift timing.

Gear changes from second to sixth gear ratios are accomplished with a precise clutch-to-clutch action, where the clutch is engaged in one gear at exactly the same time it is released in another. The first-to-second upshift, however, is a freewheeling action, where the second gear clutch engages while the first gear one-way clutch spins freely. This allows a greater degree of smoothness at lower vehicle speeds.

Adaptive Shift Controls

Adaptive shift controls include automatic grade braking, which commands the transmission to remain in a lower gear if the vehicle is decelerating or coasting on a downgrade. This takes advantage of engine braking to prevent unwanted acceleration. This reduces the need for the driver to brake during a hill descent. The control module receives input that monitors brake pedal usage, vehicle acceleration rate, throttle position, and even whether a trailer is connected to the vehicle.

Compact Dimensions

State-of-the-art dimensions enable spacious packaging and enhance potential safety design opportunities. In addition, styling opportunities for lower hood lines are also enabled by the compact dimensions of the 6T70 and 6T75.

Space-Saving Hyper-Elliptical Torque Converter

The 246 mm torque converter in the 6T70/6T75 uses a 258-mm single-plate lock-up clutch and features a “hyper-elliptical” oval cross-section shape. This design reduces the thickness of the torque converter, reducing the space it needs and keeping the overall width of the engine and transmission as narrow as possible, for packaging advantages. The single-plate lock-up clutch uses GM’s electronically controlled capacity clutch (ECCC) technology to help dampen engine vibrations and ensure smooth operation.

Vane-Type Variable-Capacity Pump

A chain-driven, off-axis fluid pump provides hydraulic pressure for the shift events and lubrication. The pump features vanes that can vary its output, optimizing the amount of energy the pump needs to operate. Internal tests have demonstrated improved powertrain efficiency with the variable-capacity pump.

Ground And Honed Gears

To minimize gear noise, as well as vibration, the transmissions’ helical gears are ground and honed to ensure exact dimensions and tolerances. With closer tolerances, the gears are less prone to characteristic whining or humming, and the transmissions operate with exceptional quietness.

Unique Input Shaft Bushings

The input shaft requires no machining for grooves to contain fluid seals, which allows the shaft to retain maximum strength for its size and minimize cost.

| Type: | Six speed front-wheel-drive, electronically controlled, automatic overdrive transaxle with an electronically controlled torque converter clutch |

| Engine range: | 3.6L |

| Maximum engine torque | 301 lb-ft (406 Nm) |

| Maximum gearbox torque (all gears): | 380 lb-ft (515 Nm) |

| Gear Ratios | |

| First: | 4.484 |

| Second | 2.872 |

| Third: | 1.842 |

| Fourth: | 1.414 |

| Fifth: | 1.000 |

| Sixth: | 0.742 |

| Reverse: | 2.882 |

| Final Drive Ratio: | 3.160 |

| Maximum Input Speed | |

| Rev: | 5000 rpm |

| 1-2: | 7000 rpm |

| 2-3: | 7000 rpm |

| 3-4: | 7000 rpm |

| 4-5: | 6500 rpm |

| 5-6: | 5798 rpm |

| Maximum validated gross vehicle weight: | 2930 kg (6460 lbs) |

| Shifter Positions: | P, R, N, D, M, (DSC+/-) & L (MU/MD) |

| Case material: | Die cast aluminum |

| Shift pattern: | 6 Variable Flow Solenoids |

| Shift quality: | 6 Variable Flow Solenoids |

| Torque converter clutch: | Variable Flow Solenoid |

| Converter size: | 246 mm (diameter of torque converter turbine) |

| Fluid type: | DEXRON VI; 9986153; Spec: GMN10060 |

| Transmission weight (wet): | 104.4 – 104.7 kg (320.16 – 230.82 lbs) |

| Fluid capacity (approximate): | 9.0L (9.5 qt) |

| Bottom pan removal: | No |

| Pressure taps available: | Line Pressure |

| Transfer design: | Three-axis design |

| Assembly sites: | Warren, Michigan |

| Vehicle | Engine |

|---|---|

| Cadillac XTS Professional Vehicle | 3.6L V6 LFX NA |

| Buick Enclave | 3.6L V6 LLT NA |

| Chevrolet Traverse | 3.6L V6 LLT NA |

| GMC Acadia | 3.6L V6 LLT NA |