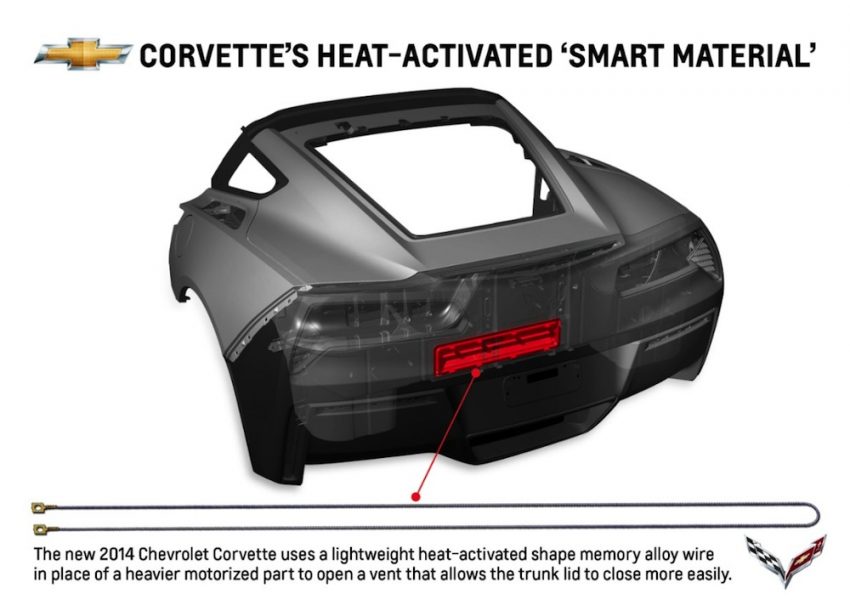

The Chevy Corvette has always been known for using new and innovative materials — like carbon fiber composites — in a structural fashion. In that regard, the 2014 Corvette C7 doesn’t disappoint, as it introduces a light yet stiff aluminum frame that improves vehicle performance while being 99 pounds lighter than its predecessor. But the new Vette also uses new materials in a dynamic fashion, becoming the first vehicle to use the GM-developed lightweight shape memory alloy wire to replace a heavier motorized actuator to open and close a hatch vent that releases air from the C7’s trunk.

You may have experienced a time when a (usually large) hatch was difficult to close. More often than not, this is usually due to trapped air inside the trunk lid. And it just so happens that Corvette engineers were able to solve the problem with a creative solution using shape memory alloys (SMA) and an air vent.

Made of copper-aluminum-nickel or nickel-titanium, SMAs are smart materials that can change their shape, strength, and/or stiffness when activated (or enabled) by heat, stress, a magnetic field, or an electrical voltage. The materials are capable of “remembering” their original shape and returning to it when de-activated. In the C7, a shape memory alloy is integrated with the active hatch vent to decrease the difficulty of closing the rear hatch door. Here’s how it works.

When the button to open the hatch is depressed, a small electrical current is passed through the SMA wire, heating up and thereby compressing the spring. This compression opens an air vent in the rear of the C7 that remains open for as long as the hatch is open. In effect, the shape memory alloy allows the compression of the spring to open the hatch vent when the deck lid is opened by the user. The open air vent then allows the user to close the trunk lid with increased ease by avoiding (or significantly reducing) the air turbulence created when moving a large solid object (such as a door) in a confined space (such as the cabin of a car). Once the trunk lid is closed, the electrical current switches off, the spring cools and returns to its original shape — thereby closing the air vent to maintain cabin temperature.

The beauty of such a solution is that it reduces the amount of motorized movable parts, which are usually heavier. Considering that there are about 200 motorized movable parts on the typical vehicle that could be replaced with lightweight smart materials, The General is looking at significant mass reduction going forward using SMAs. Of course, the removal of unwanted mass can help improve vehicle performance and fuel economy.

Specifically, the wire actuator used on the new Corvette is roughly 1.1 pounds (0.5 kilograms) lighter than a conventional motorized setup.

“Smart materials like shape memory alloys offer new possibilities for many movable vehicle features,” said Jon Lauckner, GM’s chief technology officer. “These new materials enable innovative designs and new and improved features at a lower cost than traditional motors and actuators.”

The shape memory alloy technology is the result of nearly five years of research and development on smart materials by GM, according to GM smart materials and structures researcher Paul Alexander. General Motors earned 247 patents on the technology.

This “is just the beginning”, says Alexander. “We have many more smart material applications in the pipeline that will bring even more improvements to our vehicles going forward.”

The GM Authority Take

This is yet another example of the great amount of thought and effort that went into the 2014 Corvette. Overall, it’s things like these that make us all giddy with excitement, while enabling us to believe that much more in the awesome future that lies ahead of the New GM.

Comments

Holy wow. What other goodies are hiding that we don’t know about yet? Almost feels like an easter egg hunt, but cool instead of just funny. 😉

Incredibly creative and impressive. I certainly the patents protect GM from having this technology swiped! This is an amazing commitment to innovative research and development.

I like it. Like the rest of the the Vette; from it’s front and rear flat composite springs, to it’s pushrod V8 engine, it’s all about simple and elegant engineering.