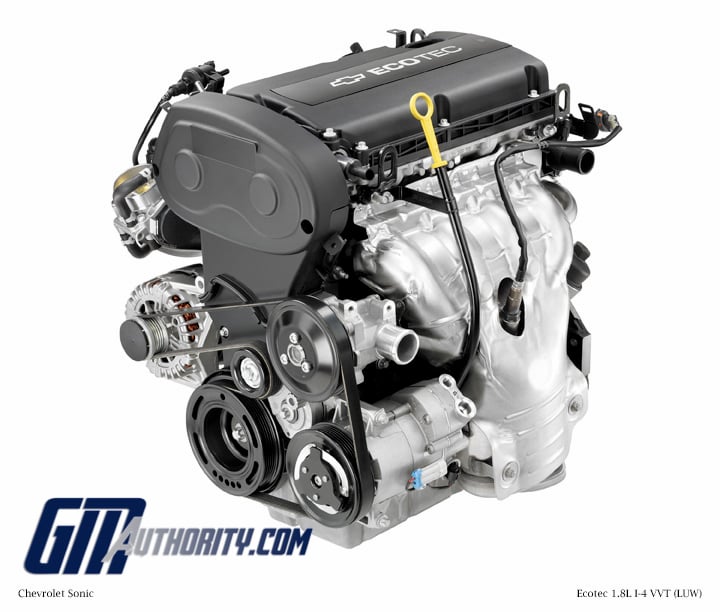

The 1.8 liter LUW/LWE inline four cylinder engine is produced by General Motors for use in subcompact and compact vehicles. It is part of the third generation of GM’s Family 1 engine family.

The 1.8L I4 Ecotec LUW/LWE delivers a balance of performance and efficiency, combining competitive output with sophisticated technologies such as dual continuous variable cam phasing (DCVCP), variable-geometry intake manifold, electronically controlled thermostat, and engine oil cooler with low maintenance, low emissions, and outstanding fuel economy.

Engine highlights include:

- Cylinder Block: the LUW/LWE’s cylinder block is based on the proven hollow-frame concept. Gray cast iron provides an extremely durable foundation, optimized with a deep skirt that minimizes both wear and vibration. A structural aluminum oil pan further reduces noise, vibration and harshness, increasing the powertrain’s rigidity and ensuring efficient heat transfer from the block. The 1.8L block supports greater loads than that used in previous generation engines, while improving the overall rigidity of the engine/transmission assembly.

- Less Reciprocating Mass: like the pistons, other reciprocating components in the 1.8L were developed for an optimum mix of strength, balance, and low weight. The result is less reciprocating mass inside the engine, increasing efficiency and enhancing the tactile feeling of performance as the engine builds revs. The steel connecting rods incorporate a larger, forged I-beam cross section for added strength without increasing weight.

- Floating-Pin Pistons With Oil-Spray Cooling: the LUW/LWE’s pistons feature a floating-pin design where the wrist pins, which attach the piston to the connecting rod, “float” inside the rod bushing and pin bores in the piston barrel. Compared to a conventional fixed pin assembly, in which the connecting rod is fixed to the piston’s wrist pin and the pin rotates in the pin bore, the floating pins reduce stress on the pin. This allows tighter pin to pin-bore tolerances and reduces noise generated as the piston moves through the cylinder. The benefit is less engine wear, improved durability, and quieter operation. The 1.8L LUW/LWE’s pistons also have oil-spray cooling, where each piston has its own individual directed jet that sprays oil toward its skirt, coating its underside and the cylinder wall with an additional layer of lubricant. The extra lubrication cools the pistons, reducing friction and helping ensure durability. Additional oil on the cylinder walls and wristpin also dampens noise emanating from the pistons.

- Variable Valve Timing: variable Valve Timing (VVT) helps the Ecotec 1.8L deliver optimal performance and efficiency, along with reduced emissions. VVT allows linear delivery of torque, with near-peak levels over a broad rpm range and high specific output (horsepower per liter of displacement), without sacrificing overall engine response or driveability. It also provides another effective tool for controlling exhaust emissions. And because VVT manages valve overlap at optimum levels, it eliminates the need for an Exhaust Gas Recirculation (EGR) system.

- Hollow-Cast And Chain-Driven Camshafts: the pair of camshafts in the 1.8L Ecotec LUW/LWE are hollow and lighter than conventional solid shafts. Along with helping reduce the overall weight of the engine, they lower the inertia of the valvetrain, allowing the engine to rev higher and more quickly.

- Modified Variable Two Step Runner Length Intake Manifold: the lateral position of the throttle valve permits an optimum port formation of the single manifold runners in connection with a reduction of the losses in the fresh air section from the air filter to the intake valve. The cross-section of the runners is constant over the entire length. The runner length in the power mode is 40 percent of the torque mode. In order to minimize the flow resistance at high speeds, a rotary sleeve was used instead of a flap-switching device. This solution guarantees the maximum possible cross-sectional area in the open position. Another advantage of the rotary sleeve design is that a high tightness can be reached in the closed position.

- Improved Lubrication: to improve thermal management, and to ensure adequate oil supply for the cam phasers and piston jets, a liquid-to-liquid oil cooler is mounted on the exhaust side of the engine block. The cooler is compact and lightweight (less than three pounds), and provides a significant decrease in oil temperature without a decrease in average oil pressure. The oil cooler is cooled by the cooling system via a dedicated coolant passage in the engine block. While the design cools the oil in the normal operating temperature range, it also allows the oil to warm more quickly. That means optimal viscosity and friction reduction sooner after a cold start. The oil pump’s flow volume is matched to the engine. The pump is packaged in an assembly module with the water pump, timing belt cover and fastening points for accessories. This unique module reduces assembly time and improves build consistency.

- Advanced Cooling System: the 1.8L features an electronically controlled thermostat in a lightweight, heat-resistant plastic housing. The electronic thermostat allows more precise temperature control than a conventional thermostat, and can be opened and closed by the engine control module (ECM), rather than at a default coolant temperature. The 1.8L’s cooling circuit was developed using extensive Computational Fluid Dynamics analysis. The result is appropriate engine cooling with the least amount of coolant volume—and weight.

- Stainless Steel Exhaust Manifold With Close-Coupled Catalytic Converter: the stainless steel manifold is lighter than conventional cast iron. It reduces friction and smoothes the flow of air so exhaust gas can be rapidly expelled. The close-coupled catalyst substantially lowers emissions during cold starts, or the brief period when an engine operates at its highest emissions level. Because the exhaust ports and exhaust manifold heat more rapidly than any part of an engine, moving a smaller catalytic converter closer to the manifold allows the catalyst to heat more quickly. So positioned, the catalyst achieves light-off the temperature at which exhaust emissions are most efficiently oxidized sooner.

| Type: | 1.8L I4 Fam1 Gen3 |

| Displacement: | 1796cc (110 ci) |

| Engine Orientation: | Transverse |

| Compression ratio: | 10.5:1 |

| Valve configuration: | Dual Overhead Camshafts (DVCVP) |

| valves per cylinder: | 4 |

| Assembly site: | Bupyeoung, Korea or Toluca, Mexico |

| Valve lifters: | Direct acting tappet with hydraulic lash adjuster |

| Firing order: | 1 – 3 – 4 – 2 |

| Bore x stroke: | 80.50 x 88.2 mm |

| Bore Center (mm): | 86 |

| Bore Area (cm2): | 203.61 |

| Fuel system: | Sequential fuel injection |

| Fuel Type: | Regular unleaded |

| Applications | Horsepower hp (kW) |

| Chevrolet Cruze: | 138 hp (103 kW) @ 6300 rpm SAE Certified |

| Chevrolet Sonic: | 138 hp (103 kW) @ 6300 rpm SAE Certified |

| Applications | Torque lb.-ft. (Nm) |

| Chevrolet Cruze: | 125 lb.-ft. (170 Nm) @ 3800 rpm SAE Certified |

| Chevrolet Sonic: | 125 lb.-ft. (170 Nm) @ 3800 rpm SAE Certified |

| Maximum Engine Speed: | 6500 rpm |

| Emissions Summary: | GM System 0 Engine Management System with E83 ECM |

| Federal: Tier 2 BIN 4 | |

| California: BIN 4 (ULEV2 Qualified) | |

| Materials | |

| Block: | Cast Grey Iron (hollow frame) |

| Cylinder head: | Cast Aluminum |

| Intake manifold: | Composite |

| Exhaust manifold: | Fabricated Stainless Steel Maniverter 4-1 |

| Crankshaft: | Cast Nodular Iron |

| Camshaft: | Cast Chilled Iron |

| Connecting rods: | Forged Steel |

| Additional features: | Double Continuous Variable Cam Phasing (DCVCP) |

| Varible Two Step Runner Length Intake Manifold | |

| Electronic Throttle Control | |

| Electronic Controlled Cooling System | |

| Hydraulic Tappets | |

| Cylinder Selective Adaptive Knock Control | |

| Engine Oil Cooler with Individual Piston Cooling Jets | |

| Individual Coil on Plug High Energy Ignition | |

| Extended Life Coolant | |

| 3 Layer Sheet Metal Cylinder Head Gasket | |

| Belt Driven Camshaft | |

| Long life (100,000-mile) spark plugs | |

| Vehicle | Transmission |

|---|---|

| Chevrolet Cruze | MH9-6T30 |

| MZ0-M32-6 | |

| Chevrolet Sonic | MH9-6T30 |

| M26-F17-5 |

Even though they have different engine codes, the LUW and LWE are identical engines, with no perceptible differences in specifications or performance. It is unclear why they have two distinct production codes.

[nggallery id=529]