General Motors will produce up to 30,000 ventilators between now and late August as part of its efforts to support the United States’ battle against the novel coronavirus (COVID-19).

The GM ventilators will be built under a $490 million government contract under the Defense Production Act. It will deliver just over 6,000 of the ventilators by June 1st, though it had previously to be making 10,000 a month by mid-April.

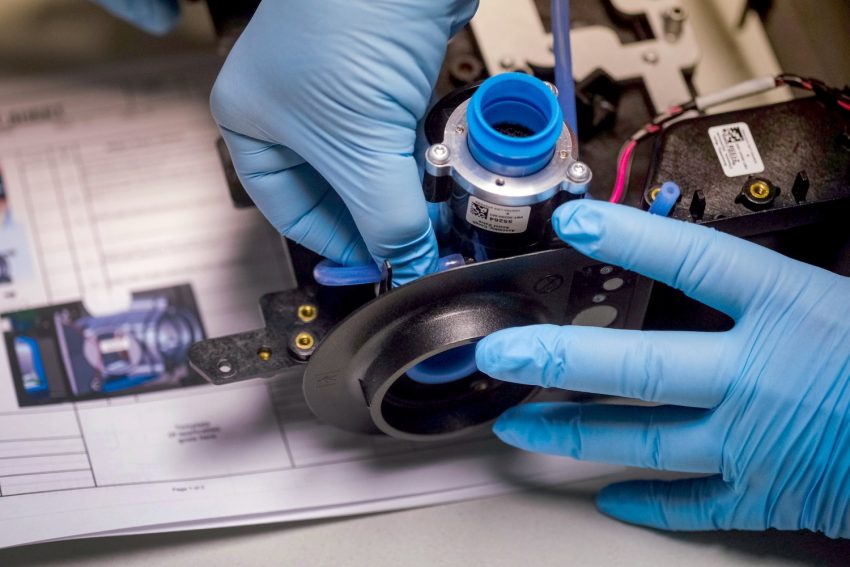

GM has repurposed one of its parts production facilities in Kokomo, Indiana for ventilator production and partnered with Ventec Life Systems to produce its VOCSN ventilator design. In a statement released last month, Ventec CEO Chris Kiple said the response to the pandemic was “unprecedented” and praised GM and its suppliers for their “incredible” support in making the life-saving machines.

“Healthcare professionals on the front lines deserve the best tools to treat patients and precision critical care ventilators like VOCSN are what is necessary to save lives,” Kiple added.

GM has also implemented strict measures at the Kokomo plant to protect workers who are manufacturing the ventilators. When employees arrive, they are required to immediately sanitize their hands and have their temperature checked with a non-contact thermometer. They are also required to wear a medical-grade protective face mask, which the automaker is currently producing at its Warren Transmission plant in Michigan. Only a single employee mans each work station, which are spaced at least six feet apart. Cleaning crews also sanitize common touch surfaces throughout the day, as well as worker common areas such as the lunch room. This is done at least three times per shift.

“The men and women building these ventilators raised their hands to help save the lives of people suffering from COVID-19,” said GM’s corporate medical director, Dr. Jeffery E. Hess. “We will create a safe workplace using CDC guidelines and scientific data.”

Roughly 1,000 employees are building ventilators at the Kokomo plant. Some of the employees already worked at the Kokomo facility, while others were pulled from the nearby Marion Metal Center stamping plant.

Subscribe to GM Authority for more GM-related COVID-19 news and around-the-clock General Motors news coverage.

Comments

why hospitals want vents. a doc was just on TV saying the federal govt pays $19K if a person is admitted a hospital with the virus and get an additional $39 K if put on a ventilator. he said hospitals are using this to make money because if they admit them with heart failure the payment is less. so a lot of these deaths are really caused by something else like heart failure they use the virus to make money. no wonder cuomo wanted 40,000 vents for the NY state hospitals.

Unless the Kokomo plant had a lot of unused production area, I can’t imagine that the assembly of ventilators really need THAT much space to necessitate to retool some other production line. They’re not big devices! I’m sure GM and the ventilator company could have found a former, now closed Walmart, Kmart or Sam’s Club sitting idle, and looking for a tenant, that would have more than enough space for assembly lines. From what I understand, this operation is only to be a short-term project, for six to 10 months, until the ventilator supply meets healthcare needs, and backup product for future needs. I’m not under the impression that this will be an ongoing business unit for GM