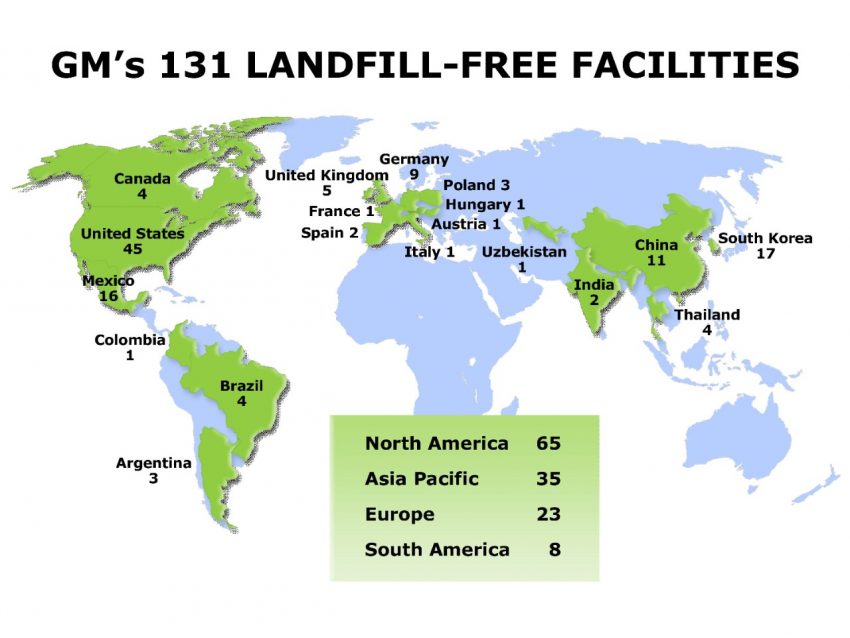

GM leads the industry with its landfill-free sites, and with the addition of six landfill-free sites in Mexico and England, the total count rises to 131 facilities. The Luton Assembly plant and Ellesmere Port Assembly plant were two of the six sites to most recently achieve landfill-free status, and that makes all 18 Opel/Vauxhall manufacturing plants in Europe landfill-free.

Hiring a waste management company that specializes in challenging byproducts versus general waste was key to Ellesmere Port Assembly’s ability to make its landfill-free status happen. Additionally, the plant is currently participating in a trial project to wash rags used to wipe up solvent, instead of using disposable rags.

“Our global progress in waste reduction is possible because of employee participation, creative ideas, and a strong supplier network,” said Jim DeLuca, GM executive vice president of Global Manufacturing. “Our teams understand the positive impact of this initiative and they drive it in their facilities every day.”

Being “landfill-free” means daily waste is recycled, reused, or converted into energy. Part of this initiative includes the washing of solvent-drenched rags as we mentioned, but also includes making shoe soles out of recycled material (more on this below). You can imagine that sorting out the used material may be a challenge for the facilities, so GM preps its employees with recycling courses and training videos to help them understand the environmental benefits, as well as the business benefits. Some plants designate a green champion in each part of the plant to drive participation.

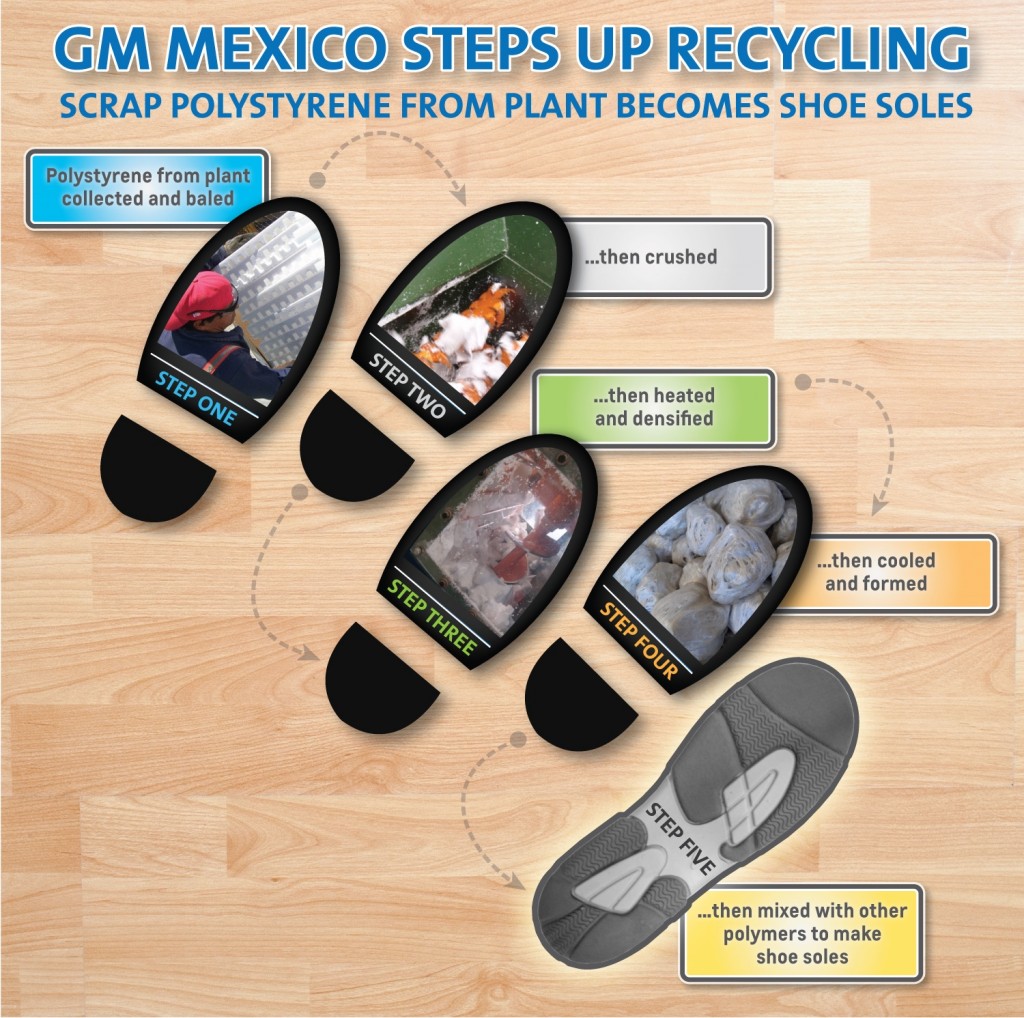

A total of 16 facilities at GM’s Toluca, Mexico complex are landfill-free. These facilities work closely with resource management suppliers to find higher uses for their byproducts, such as turning polystyrene foam packaging into footwear. This is done by taking the material to a warehouse where it is baled and sent to be crushed and densified into pellets, which are then combined with other polymers to create shoe soles.

Other new landfill-free facilities include the following:

- Uzbekistan Engine plant

- Chevrolet sales office in India

- IT Innovation center building (Georgia)

- Howell spare parts operation (Michigan)

- Customer care and aftersales facilities in Cincinnati (Ohio)

- Willow Run (Michigan)

- Rancho Cucamonga (California)

- Woodstock (Ontario, Canada)

- Langley (Vancouver, Canada).

GM’s goal is to achieve 150 landfill-free sites globally by 2020.

Comments

Outstanding efforts here , congratulations GM !!

That’s good news.

I’d be a little bit skeptical about, say, China and India,

but it’s the holidays, and I don’t want to break the festive mood.